As the tire pyrolysis plant will produce sludge deposits during the cooling process, customers should check and clean up the slag of all parts(including carbon blacking discharging machine, oil gas separator,water cooling pond, water seal and oil tank) before start next batch. The slag can be put in the reactor for second pyrolysis.

There are five factors that may lead these blockages.

(1) The heating temperature rises too rush. Leading the oil-gas didn’t be cooled in time in the oil-gas separator and water cooling pond.

Solution: Slim the fire of burner and let the temperature rises slowly.

(2) The pressure of the reactor is too large. Pushed the high temperature oil gas into following device.

Solution: Keep the pressure of reactor less than 0.02Mpa.

(3) Wrong rotating direction of reactor during pyrolysis.

Remind: there are switch which control the rotated direction of the reactor: Forward and reverse.

During pyrolysis:Keep the reactor rotated forward to make the tire move to the feed door.

When discharge the carbon black:Keep the reactor rotated reverse to make the carbon black move to the discharging machine.

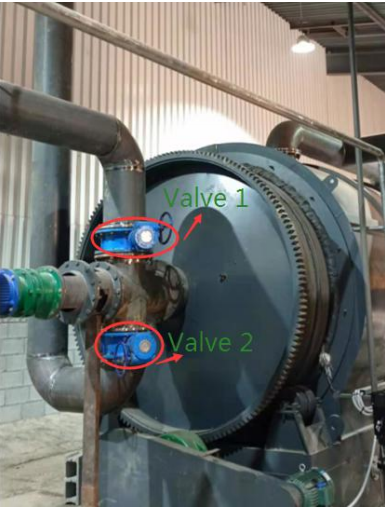

(4) When discharge carbon black,the Valve 1 is not closed.

Remind:When production,the Valve 1:open; Valve 2:Close. When discharge carbon black,the Valve 1:close; Valve 2:open.

(5) Didn’t check and clean up all parts regularly.

Solution: Clean up the following parts regularly.

|

No |

Parts Name |

Cleaning frequency |

Picture of Each Parts |

|

1 |

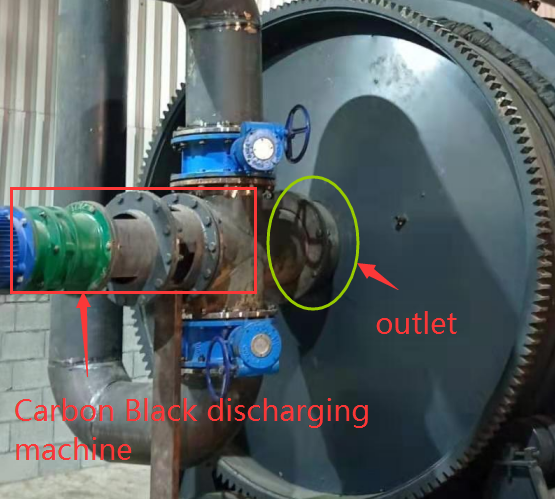

The outlet and carbon black discharging machine | need to check and clean up every batch(Go into the reactor to check before start next batch) | |

|

2 |

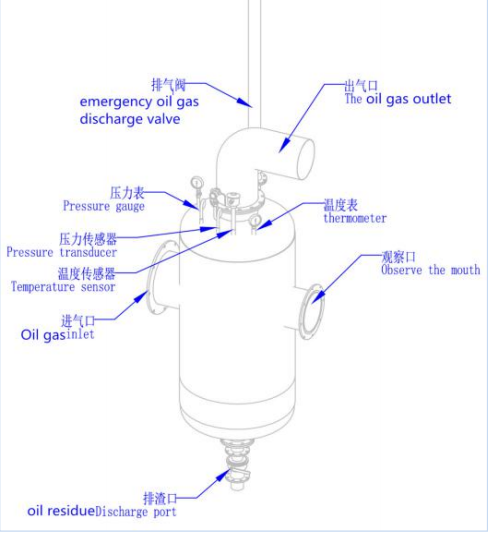

Oil gas separator | Need to discharge the oil residuel before start next batch. | |

|

3 |

Water cooling pond | Check and clean up all the pipes per 2-3 batchs(around one week) | |

|

4 |

Water Seal | Change water inside per 8-10 days. | |

|

5 |

Desulfuring Tower | Change water inside and clean the ceramic rings per 20 days. | |

|

6 |

Oil tank | Clean up per 15 dyas. |

|

|

7 |

Carbon black bin | Emptying it evey 2 batches. (You can pack the carbon black in jumbo bag) | |

|

8 |

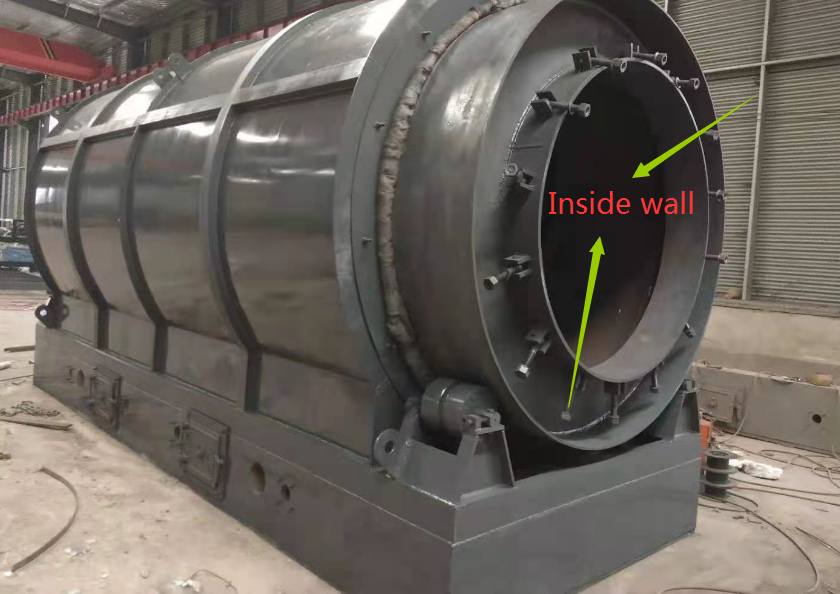

Reactor(Furnace) inner wall | Need to clean up if the coke sticking in the wall more than 5mm. |

Post time: Sep-15-2021